Getley UK | Building an empire of British kitchen manufacturing

Component kitchen and bedroom manufacturer Getley UK has been a success story since its launch and development into complete kitchens with the Alku brand. We talk to managing director Paul Bryan and marketing director Dan Hughes about future growth

Component kitchen and bedroom manufacturer Getley UK has been a success story since its launch and development into complete kitchens with the Alku brand. We talk to managing director Paul Bryan and marketing director Dan Hughes about investment in the company and future growth

An experienced team leads the complete kitchen brand Alku, with the senior management including CEOs Mark and Emanuela Getley, managing director Paul Bryan and marketing director Dan Hughes

British kitchen and bedroom manufacturer Getley UK has gone from strength to strength since its launch in 2006.

It was founded by CEOs Mark and Emanuela Getley, who owned a kitchen and bedroom retail showroom and trade outlet in Staffordshire.

Sponsored Video

Following the administration of their carcase supplier they acquired a 20,000 sqft factory and set about creating cabinets for their business and supplying local customers.

Within 12 months, encouraged by the response of local tradesmen and the volume of work, Mark and Emanuela Getley closed the showroom in Rugeley, to focus on the ambitious plan of setting up their manufacturing outlet in Stafford.

A year later, Paul Bryan joined the company, and was promoted to managing director in 2019, taking over the day-to-day running of the business.

“When I joined, we produced 100 cabinets a week, and there were six of us in the factory. It has grown to what it is today with 70 employees across two sites”.

Paul Bryan explains how the company has managed its growth “We reworked the production flow, invested heavily in new machines, recruited skilled staff and increased capacity to 1,200 cabinets a week out of the Getley site.”

A New Start

In 2020, Getley introduced Alku – the Nordic term for ‘new start’ at KBB in Birmingham. However, it’s expansion was hampered by the Covid lockdown, so was relaunched at KBB Birmingham in 2022.

Demonstrating its diverse offer, Alku can also provide Dekton sintered stone doors and ribbed vertical wood.

Alku offers 30 kitchen ranges, including Slab, Shaker and In-Frame designs, bespoke sizes and custom painting, plus 49 cabinet colours.

“We offer exceptionally good service and products, spanning the complete kitchen market that we manufacture in house” explains Dan Hughes.

Targeting mid to high-end independent studios, which focus on German kitchens, Alku was created to offer a more classic or traditional look alongside contemporary styles.

“We are not looking to replace the German suppliers; they do what they do superbly. We offer the German experience with a traditional British made product.

“We have introduced some of the services they offer such as plan-checking and panels, fillers and corner posts supplied to the customers sizes. Our principle is to focus on traditional elements that retailers can’t get from the German manufacturers”, explains Paul Bryan.

Showroom Network Growth

Alku was launched, along with a second 16,000sqft factory to cater for its expansion, and the company has invested in in-house painting facilities, machinery for timber doors and dovetail drawer boxes.

Getley opened a second 16,000sqft factory to cater for the expansion of the Alku brand and also invested in painting facilities as well as machinery to create timber doors and dove tail drawer boxes.

Currently sold through 37 national showrooms, the Alku brand has plans to double that figure.

Getley appointed brand manager Maria Langley, last year, to help connect with retail partner showrooms and to grow the brand.

Paul Bryan continues: “I believe by quarter four of this year we’ll be up to 50 to 60 showrooms. We don’t want 200 retailers all over the country. We want to be able to offer exclusivity and really drive the partnership. whilst supporting retailers with dealer protected areas.”

With the recent administration of Mereway Kitchens, it would be remiss not to consider it also offered an opportunity for establishing more Alku dealers.

As Dan Hughes acknowledges “We’ve acquired a lot of business through it” but also adds: “When you see a company struggling or failing, it’s not something we take pleasure in. Mereway was our competitor, but I have an immense amount respect for the company and its lineage’’.

Personal Touch

Predominately selling traditional kitchens, the company encourages retailers to use the ‘untapped’ experienced team at Alku to help them upsell to In-Frame.

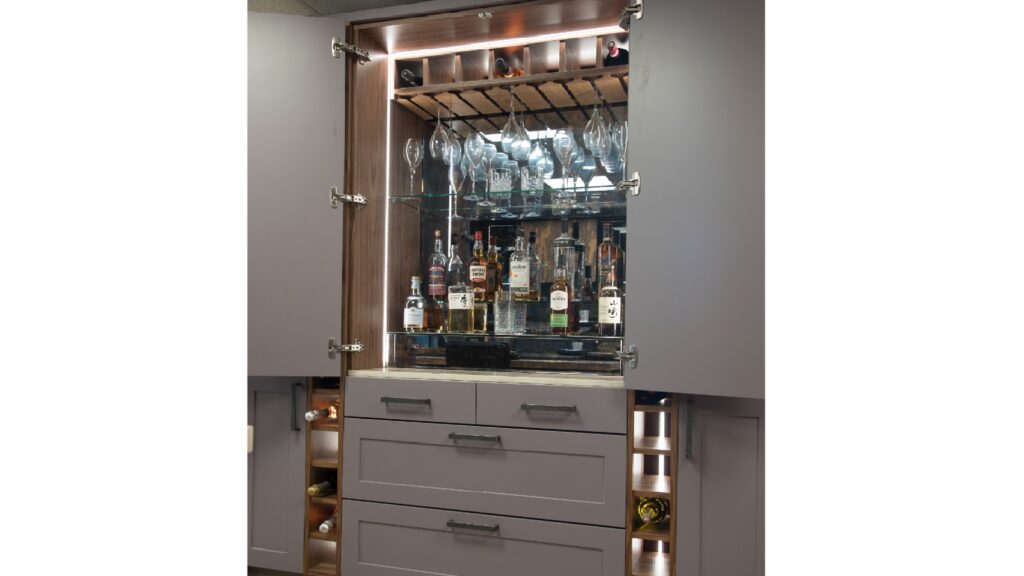

The Alku range offers coveted cocktail bars as part of its 30 strong kitchen ranges, predominately in traditional styles.

“We understand it may be daunting for a retailer that’s only ever designed a modern Germanic kitchen to have the knowledge on how to design an In-Frame, which is why we offer comprehensive one to one in-house training”, explains Hughes.

Alku provides its customers with a full list of all CAD drawings including unit sizes, hinge and feet locations.

Hughes continues: “We have regular meetings with the production and CAD teams, for every In-Frame kitchen manufactured in our factory to ensure that it’s 100% accurate, so we can iron out any potential production problems before it reaches manufacture.

“At this point we can contact the customer and ask ‘Is this correct? Are you sure you happy with the design etc? So, everyone is on the same page”.

Complete Kitchen Future

So what’s next for the Alku brand? Paul Bryan comments he is seeking sustainable growth, adding “brand awareness is something we strive for, so Alku becomes a recognised name within the industry”.

Dan Hughes notes retailers should feel safe that the business is secure. He concludes: “They need to know we’re in it for the long term.

“We’re offering our showrooms an experience in the way they trade with us. We want to strive ahead and engage with the customers more and ask what they would like to see and what they would sell if we gave them tools to do it.”

Related Articles

#socialwall

Sintered stone manufacturer Neolith has launched Calacatta Roma and Cappadocia Sunset, inspired by nature and classical architecture, and for use in kitchens or bathrooms walls, floors, in gardens or facades.

They belong to The New Classtone and Fusioncollections which interpret marble and natural stone, respectively, and boast Neolith’s antibacterial NeolEAT technology.

Inspired by Ancient Rome, Calacatta Roma (pictured top) pays homage to Italian Carrara marble, with ochre and grey veins in a white background.

While the Cappadocia region, in central Turkey, with its rock formations formed by volcanoes and underground cities, has inspired Cappadocia Sunset (pictured below).

Just like all of Neolith’s surfaces, Calacatta Roma and Cappadocia Sunset are resistant to heat and atmospheric conditions, are 100% recyclable, and do not contain added quartz to their formulation.

Mar 14, 2024

JUST OUT: @AcquabellaBath has unveiled a choice of shower grate patterns for its Base and Arq shower trays… https://t.co/kMN83c40Qf

JUST OUT: @FrankeUK unveils Mythos single lever mixers in Swivel Spout and Pull-out Nozzle options. #kitchendesign https://t.co/TSKCAo5r0e

INTERVIEW: Sales and marketing director of @blumuk David Sanders on how the kitchen industry has changed post-pand… https://t.co/k9LIpUhhDF

NEWS: Challenging housing market is driving home improvements, finds new research by @HafeleUK #HomeImprovement… https://t.co/eMB7jludIm

NEWS: British manufacturer @kudosshowersltd acquired by European SanSwiss. #acquisition #manufacturers #bathrooms https://t.co/gpOv7jMevn

NEWS: @HafeleUK announces Richard Curtis as managing director. #newhire #appointment #leadership https://t.co/NP8U5ramOb

NEWS: @officialbikbbi names CT1 sealant manufacturer as corporate sponsor. #installation #installer https://t.co/8zsxs2HI3n

NEWS: @quookeruk named one of fastest-growing companies in North West. #business #Awards https://t.co/9zZ1ZDGrFI

RETAILER FOCUS: Managing director and design director of UK Kitchen Retailer of the Year @KitchensbyJSG Jim Geddes… https://t.co/JhL3vmxwbd

NEWS: Consumers are renovating for long term, with kitchens and bathrooms a priority, finds @HouzzUK… https://t.co/9VhoTUDI0B

PROFILE: Managing Director of Flair Showers Alan Wright talks about the relaunch of the company, creation of a Show… https://t.co/WDMPqDt2Uk

The new @blumuk carbon black LEGRABOX boasts beautifully slim drawer sides, bringing furniture onto trend, easily b… https://t.co/DrEXXWTyQb

NEWS: House of Fraser owner @FrasersGroupPLC enters strategic partnership with @ao, buying a stake in the online e… https://t.co/44N0O9bekn

NEWS: @HowdensJoinery awarded @WhichUK Best Buy for its rigid cabinets and handleless kitchens. #kitchen… https://t.co/rALz8XRHbv

NEWS: @grohe invites 800 guests from around the world to its Grohe X Professional event in Lisbon, Portugal.… https://t.co/2RGjDum980

JUST OUT: Home appliance brand Candy has unveiled the Rapido dishwasher, claimed to be the fastest and most spaciou… https://t.co/mbWn2pJp2C

Newsletter

Sign up to receive our newsletter and we’ll send you details of our latest videos, competitions and much more